Mid-Season update for AMRA, USRA, IMCA, and Wissota competitors

Before I get into the mid-season update, I have one more point to make on the idiotic decisions we’ve seen from some chassis builders this season throughout IMCA, USRA, and UMP / AMRA events. I’m referring of course to the rash of 0.065″ wall thickness roll cages showing up in these different sanctioning bodies. So far we’ve heard everything from “we only did it because our customer asked us to” as well as the argument “the type of steel we used was just as strong in 0.065″ wall thickness as 0.095″ wall thickness DOM”. The “we only did it because our customer asked us to” defense is really no defense at all. It’s stupidity, and it is irresponsible. A customer is just that, a customer. They do not own the business, the assume no liability for the business, and they should have no say in a business’ decisions on safety and well-being of other racers. There is no defense to that.

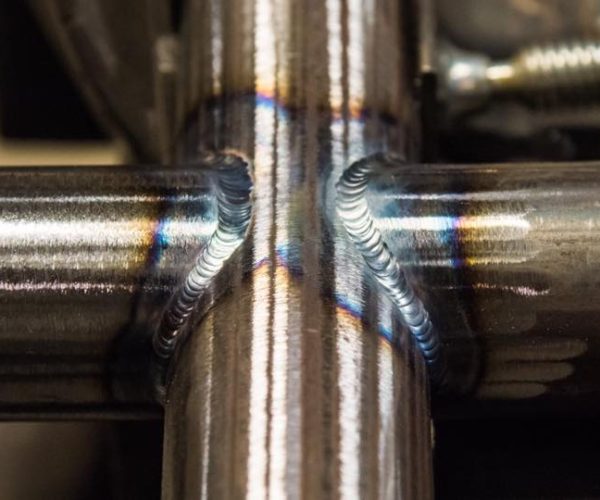

Now, onto the “0.065 inch thick 4130 is as strong as o.095 inch thick DOM” defense. Yes, that statement is accurate in a perfect world, with perfect conditions, perfect fit-up of tubing, and perfect welds. The problem (other than being against the rules) is that none of the cars I’ve seen thus far with 0.065″ thick 4130 tubing cages have met any of those criteria. They appear to have been built using the same processes and procedures as a basic 0.095″ wall thickness DOM tubing chassis, and in most instances these processes and procedures are inadequate for the thinner, more heat sensitive 4130 tubing varieties. I’m not in the camp that says 4130 can never be mig welded. I’ve seen that statement proven wrong multiple times. I will however maintain that all the steps involved in building a 4130 structure (especially in thinner tubing) are more delicate, and require much more attention to detail. And in reality, although it can be mig welded, I’d heavily suggest the ultra-thin 4130 varieties be tig welded by someone who knows what they’re doing when we’re talking about roll cages, and keeping people alive when a night at the track goes bad. The 0.065 inch thick cages are 30 lbs lighter (max) than a legal cage. Sure, it’s 30 lbs, but it’s 30 lbs right in the center of the car, which has a relatively small to non-existent effect on handling. Put into simple terms…if your chassis builder is building a car with a 0.065 inch thick roll cage, find another chassis builder as there are many great options available to you.

As far as our mid-season update goes, we’re currently sitting at the highest number of wins we’ve ever had at this point in the season, and we’ve done so with a very small number of cars in regular competition. When averaging all of our finishes for the year, we’re averaging roughly a fourth place finish with all of our drivers who compete regularly in USRA, IMCA, AMRA, and Wissota events. That is a very solid number, and we are very proud of our teams for how well they’re doing in competition.

Up until this year, we’ve been average a small number of cars per year, usually around 6. However at this point in 2017 we are currently backlogged 15 cars due to the success our teams are seeing from the east cost to the west coast. We are currently running both chassis jigs so that we can keep cars rolling out to our customers in a timely manner. Watching the growth we’ve experienced this year has been very exciting, and we’re doing our best to keep the best people we can in the shop so that as our clientele grows larger, our quality continues to stay at the highest possible level.

Congrats to all of our teams on such a solid first half of the season. We’re really looking forward to seeing what we can do as the tracks slick up in the warmer weather!

Good luck at the track!